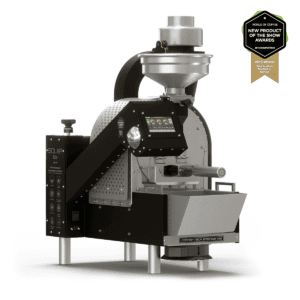

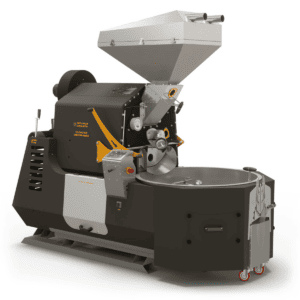

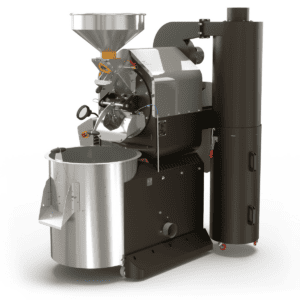

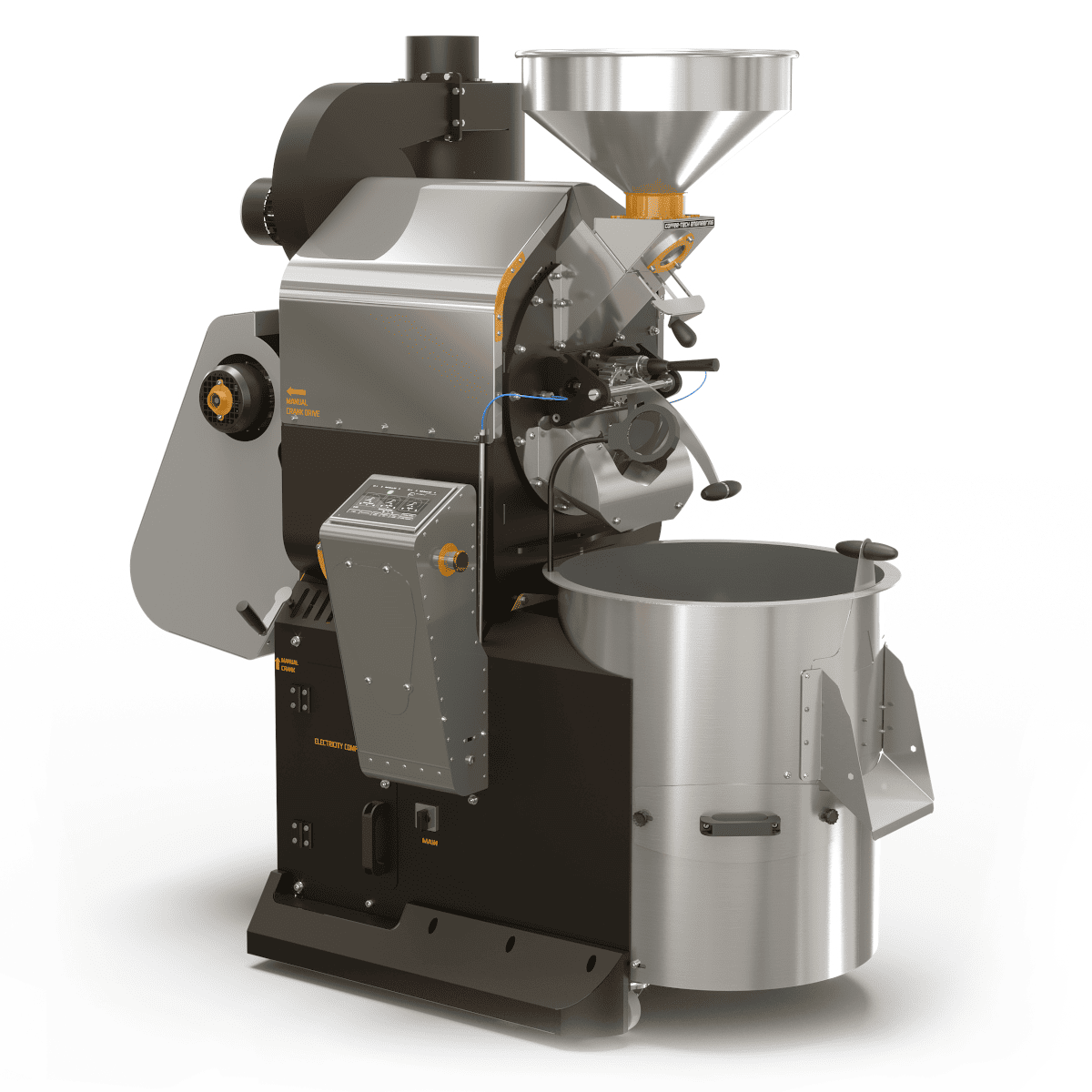

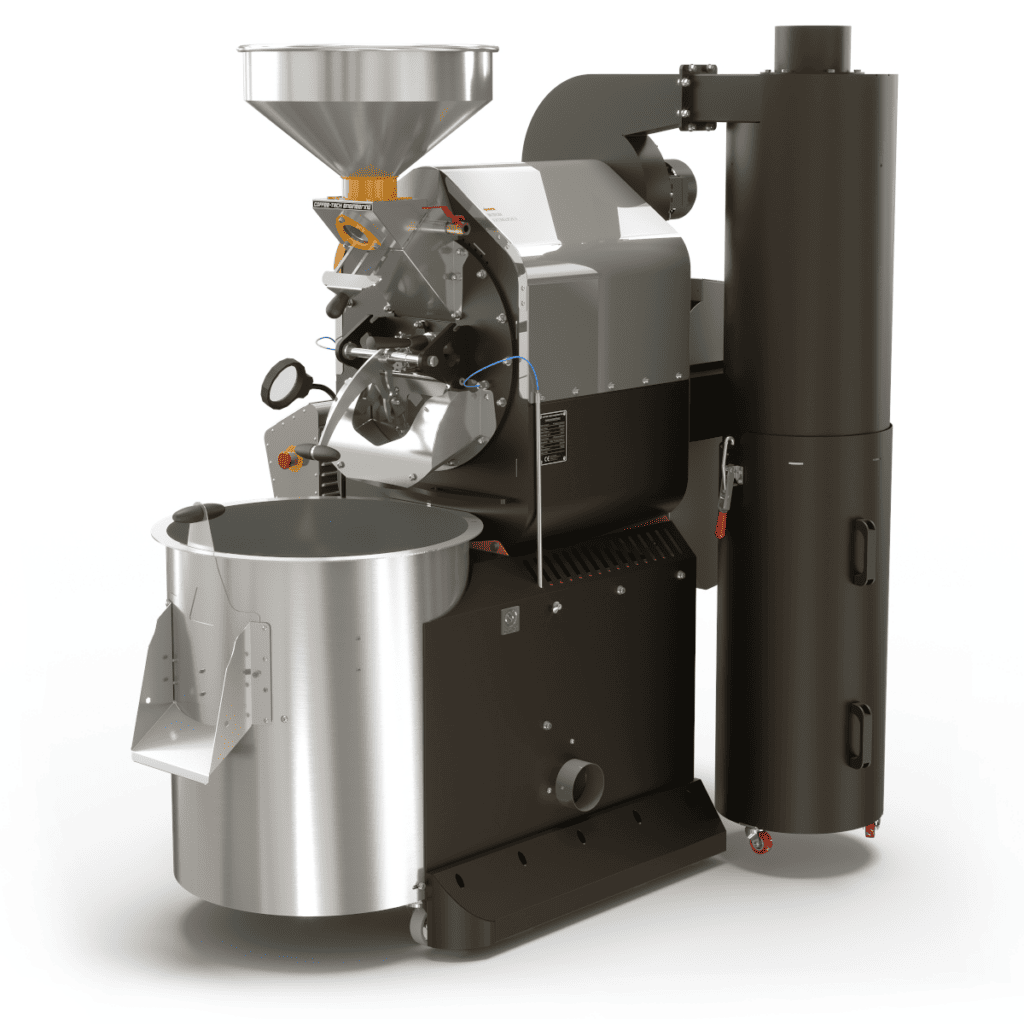

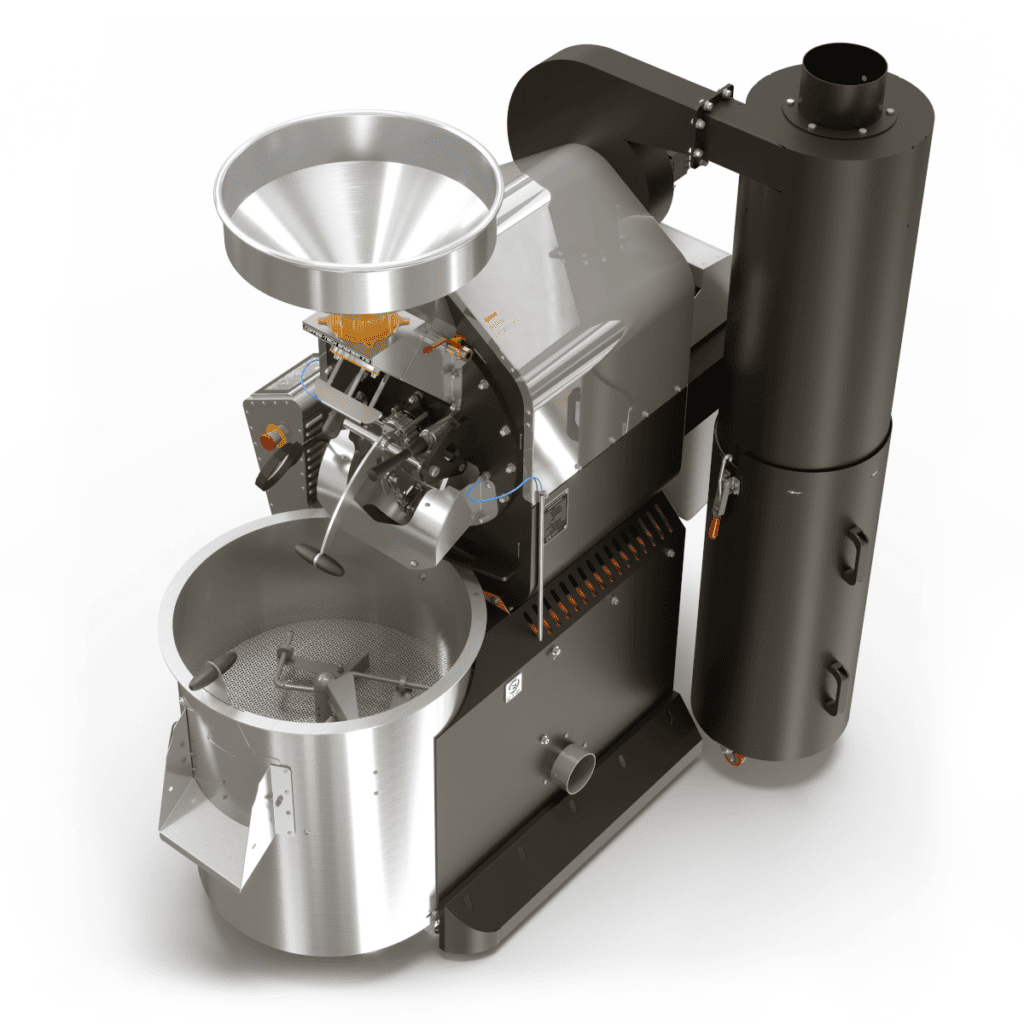

Ghibli R15 Commercial Roaster

CAD 56,406.00

1 in stock

Leasing options are available through our partners.

Make an inquiry

3-15Kg Batch Capacity

Turbo Gas Burner

Touch Screen Control

A high-tech and high-end commercial roaster.

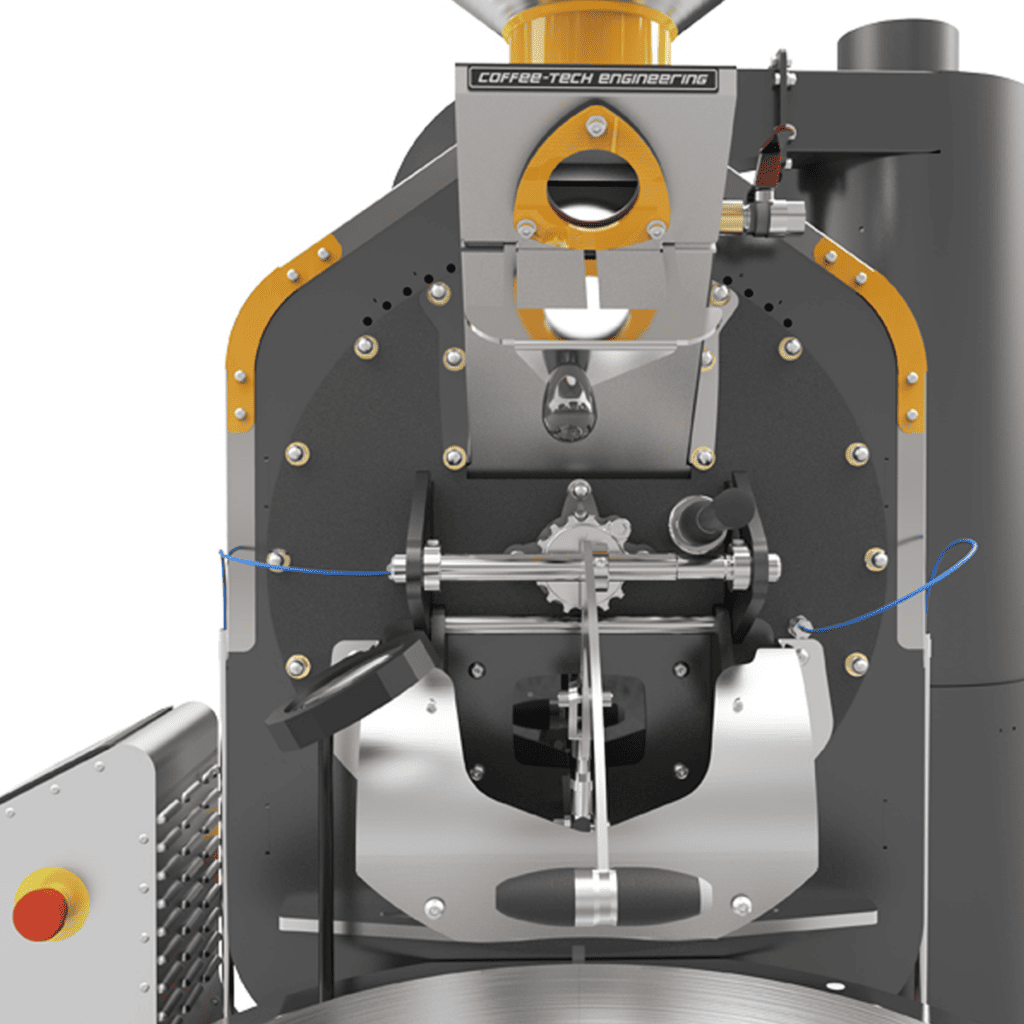

The Ghibli R15 commercial coffee roaster was designed to provide the latest technology for those who appreciate quality and deserve the best. It’s much more than a rotating “barrel on flames” – it’s created using the most advanced product design software, from beginning to end and will ensure reliable operation together with consistent, superb results for many years to come. The Ghibli features:

- Advanced thermodynamic characterization.

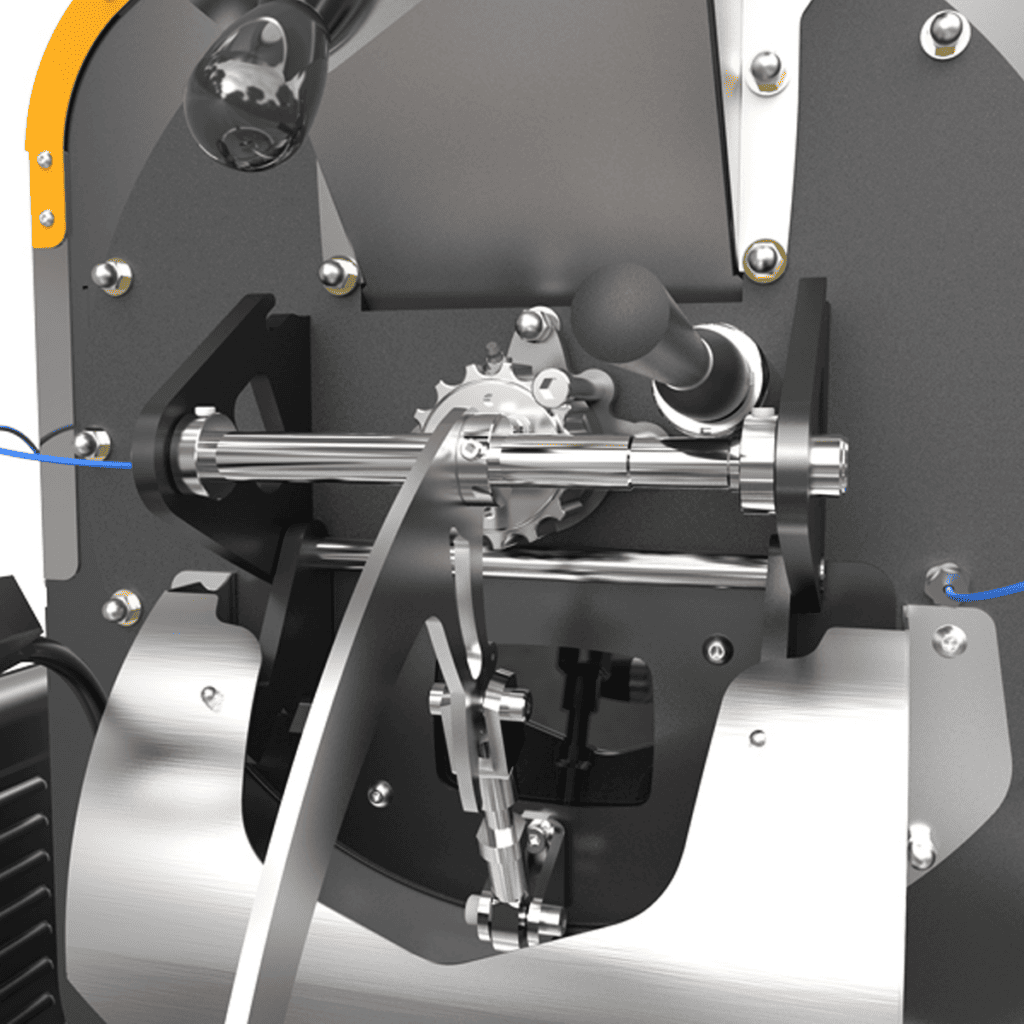

- Robust and accurate drum housing, ensuring that the drum will spin “in-line” for the entire life of the product.

- Drum proportion – achieving an optimal ratio between heat conduction and heat convection.

- In-drum agitation designed for perfect bean stirring, greater heat conduction between metal and beans, chaff separation and the immediate evacuation of the beans from the drum into the cooling group.

- Perfect heat dispersion – as a result of an intensively researched ceramic combustion chamber, optimally located against the drum, spreading heat equally throughout the drum, as opposed to the more common setup of heat being directly applied to the drum at a single point.

Unique Roasting Software

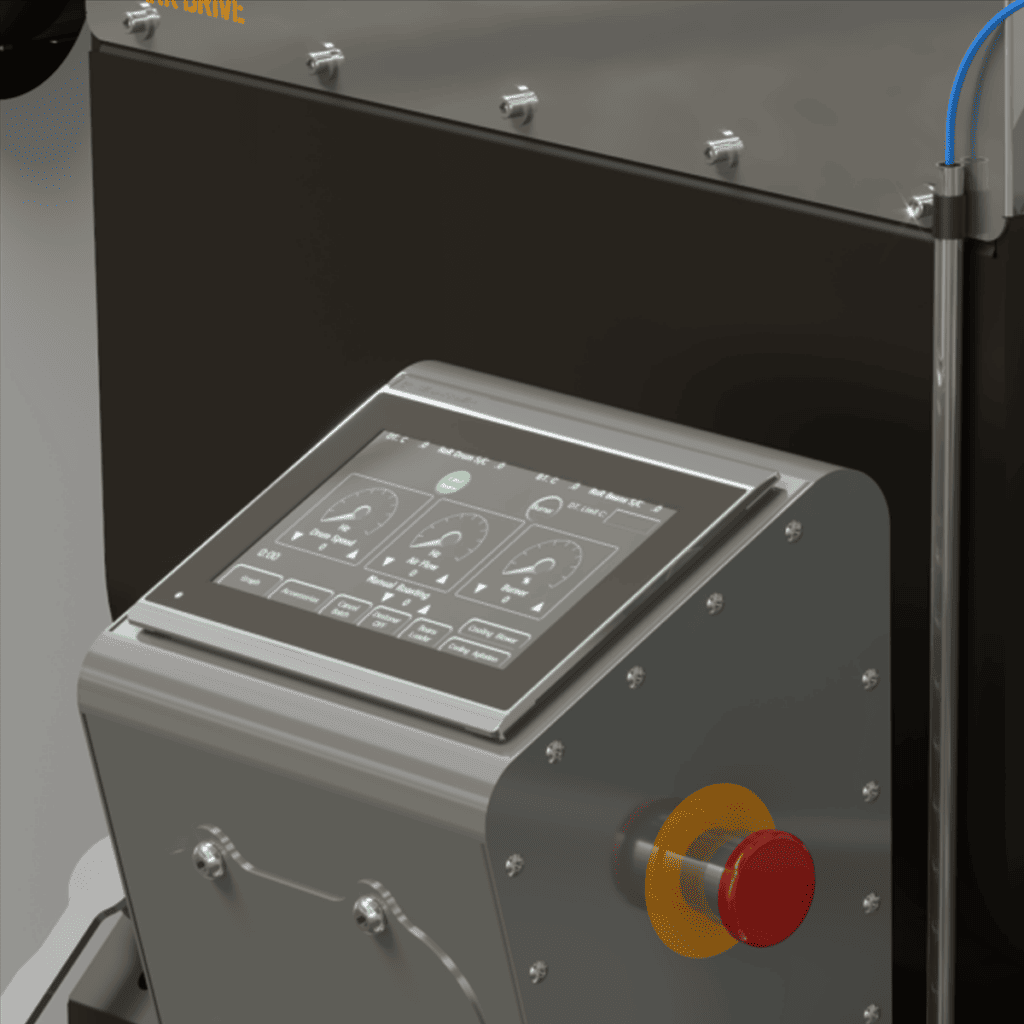

A unique roasting software developed exclusively by Coffee-Tech Engineering, enabling the user to predefine and program personal roast profiles. By recording the desired heating curves, endless roast profiles can be applied, again and again, with the greatest accuracy.

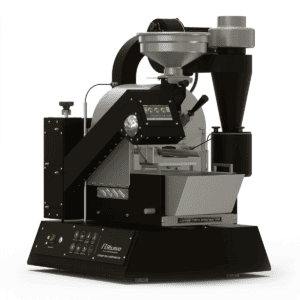

The Next-Gen Vortex TO4 Roasting Drum

In Ghibli R15, airstream blasts in spiral motion into the drum and through the coffee beans, requiring smaller amount of air to enter the roaster for a full effect.

The longer spiral path across the drum and through the coffee bed is unlike the olden traditional roaster mechanisms, which had a perforated back plate allowing huge amounts of air into the drum in a short, straight path. With our roaster, the beans are not stripped away from their coffee goodness, while the energy is also used to maintain the heat right next to the exhaust without working on the coffee itself. This innovative approach ensures a unique added-value offering for cost-effectiveness, energy optimization, and enhanced flavor.

Lab tests have shown a huge improvement in the coffee’s solids content and density, with amazing improvements in gas consumption, roasting time, fume emission.

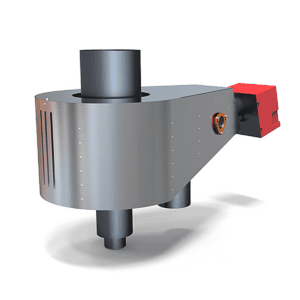

Clean, Efficient and Safe Heating System

Coffee-Tech’s entire Ghibli line features a highly efficient turbo gas burner. This clean heat source provides maximum gas burning efficiency with minimum levels of carbon monoxide emission. Safe, economical and stable, it features many unique parameters for control and calibration, described in detail in our user manual.

Comprehensive Set of Features

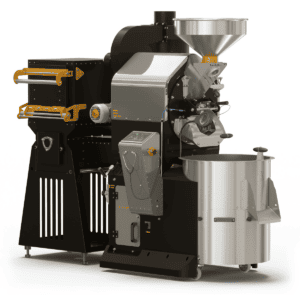

Coffee-Tech Engineering has paid special attention to the less than obvious details, such as the compact, efficient structure of the roaster, batch cooling time, drum evacuation time, the size of the monitoring control lens and drum-gate, an additional lens in the green bean hopper and more. At the end of the cycle, the entire roasted batch is transferred to the cooling group in a matter of seconds. This external group is made of 100% stainless steel with special food-grade material agitation blades which efficiently shuffle the beans over the cooling mesh. Aided by a high capacity blower, an entire batch is cooled in less than four minutes. The features above are often ignored details and their PP impact is tangible in the finished brew. Thanks to the cutting-edge technology of the machine, the roasting process achieves excellent levels of sugar, aromatic oil and a wide aromatic range. These virtues are achieved without burning the “woody” substance of the bean.

The Perfect Roasting System

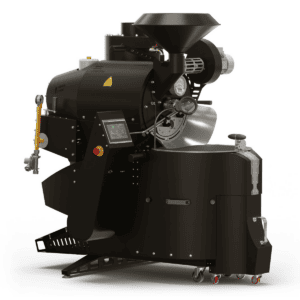

Determining a high level of conductive heat has proved the best method for producing a rich cup and this is the Ghibli R15 differ from other manufactures. Since conduction is complicated and presents several unresolved issues, many have abandoned it in favour of convective heat. Coffee-Tech Engineering has invested in extensive research in order to solve these issues. In doing so, they have designed the Ghibli R15 to roasts continuously, while cooling takes place outside the drum, making it possible to roast up to 60 kg of beans per hour. The Ghibli R15 is user-friendly, ergonomic, quiet, compact and safe. Each function has an individual motor and heat protection. This is a result of CAD design and the use of high quality materials, components and precise manufacturing tools assembled and completed by Coffee-Tech Engineering’s passionate artisans.

The Ghibli R15 is available with various heating methods, from natural gas and LPG, to traditional wood and charcoal heating, according to the customer’s preference. As a high-end roaster, the Ghibli R15 will ensure reliable operation together with consistent, superb results for many years to come.

Technology & Features

Drum Roasting

The primary roasting method in this roaster is drum roasting conduction.

Conduction Heating

Heat is delivered by direct contact between the beans and the hot surface of the drum.

Convection Heating

Hot air is forced through the beans.

Multi Point Temperature

Temperature probes gather thermal data from the beans, exhaust & drum space.

Indirect Flame

Flame is not in direct contact with the drum to ensure even and mild conduction roasting.

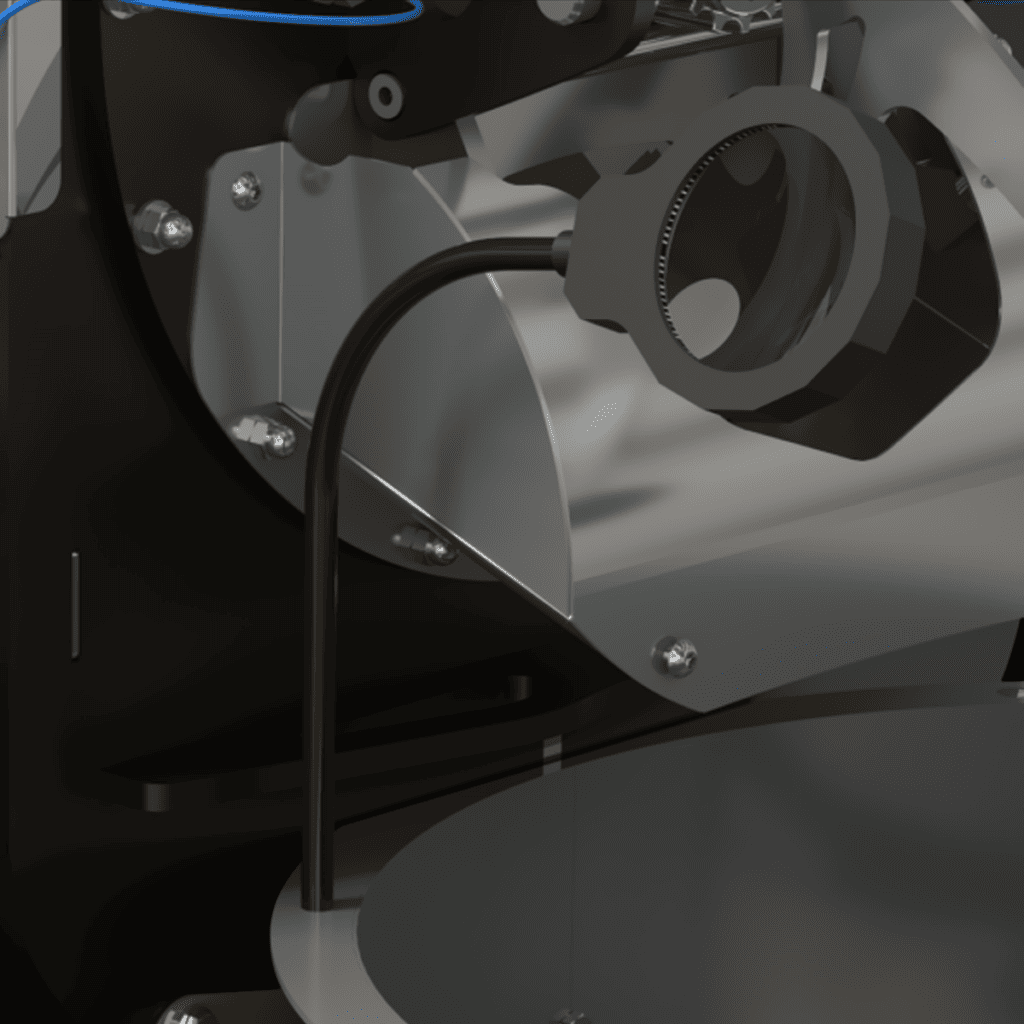

In-Drum Extinguisher

Safety device, a live waterline connected to the drum in case of in-drum fire.

Automatic

(Optional) Operation is run automatically and handled by an Automatic Roasting Management Software.

Ceramic Chamber

A ceramic-coated chamber surrounding the drum ensures thermal stability and efficiency.

Roast Data Logger

A PC-supported profile software, featuring bean temp’, drum temp’ and rate-of-rise graph.

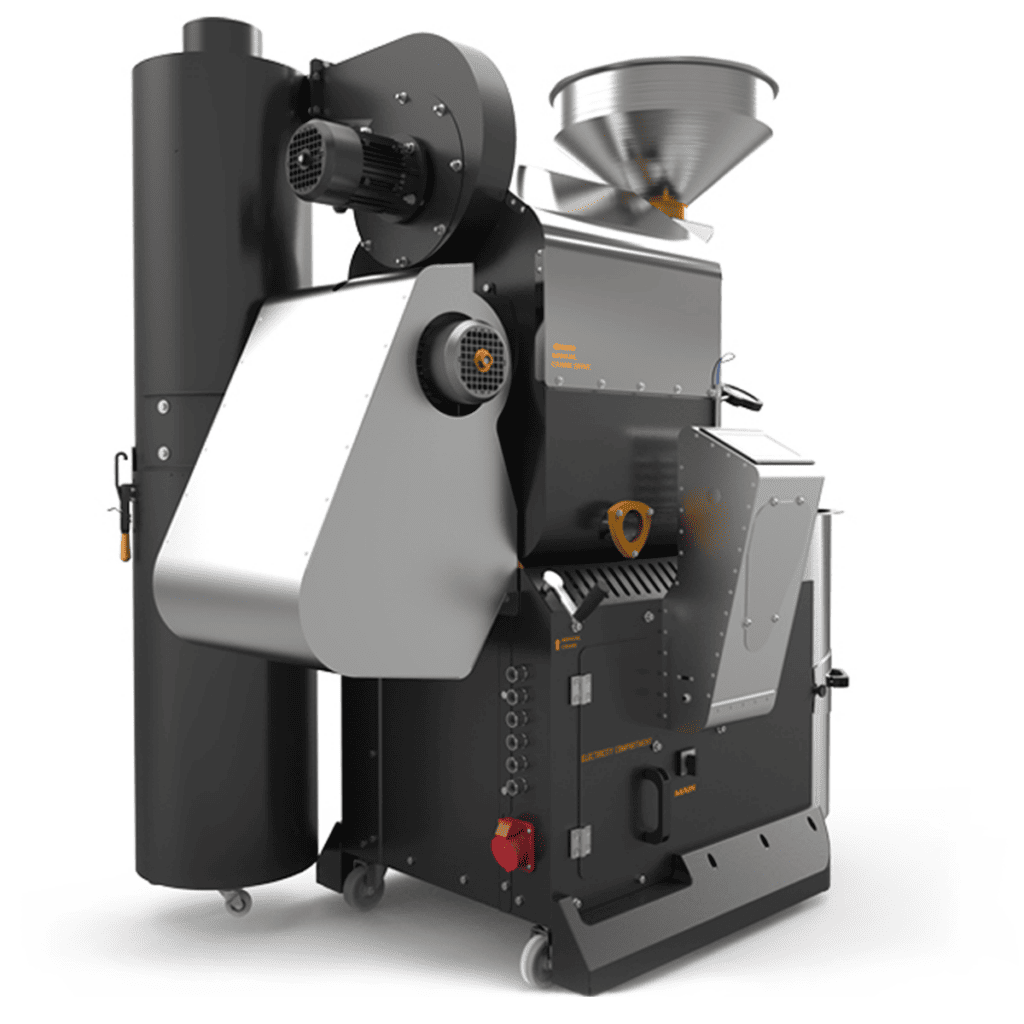

Blower Speed Control

Electronic drum venting control, setting convective heat percentage while roasting.

Drum Speed Control

Electronic drum speed control, setting conductive heat percentage while roasting.

Low Energy Consumption

Energy efficient product, low electricity consumption

Green Product

(Optional) This product excels in its low rates of emission and air pollution.

Smoke-Free

(Optional) An efficient and green smoke elimination system.

Low-NOx

Ultra-low NOx specs fulfill the strictest pollution standards.

Manual Safety Crank

The manual safety crank allows you to manually evacuate your beans should your roaster lose its power supply.

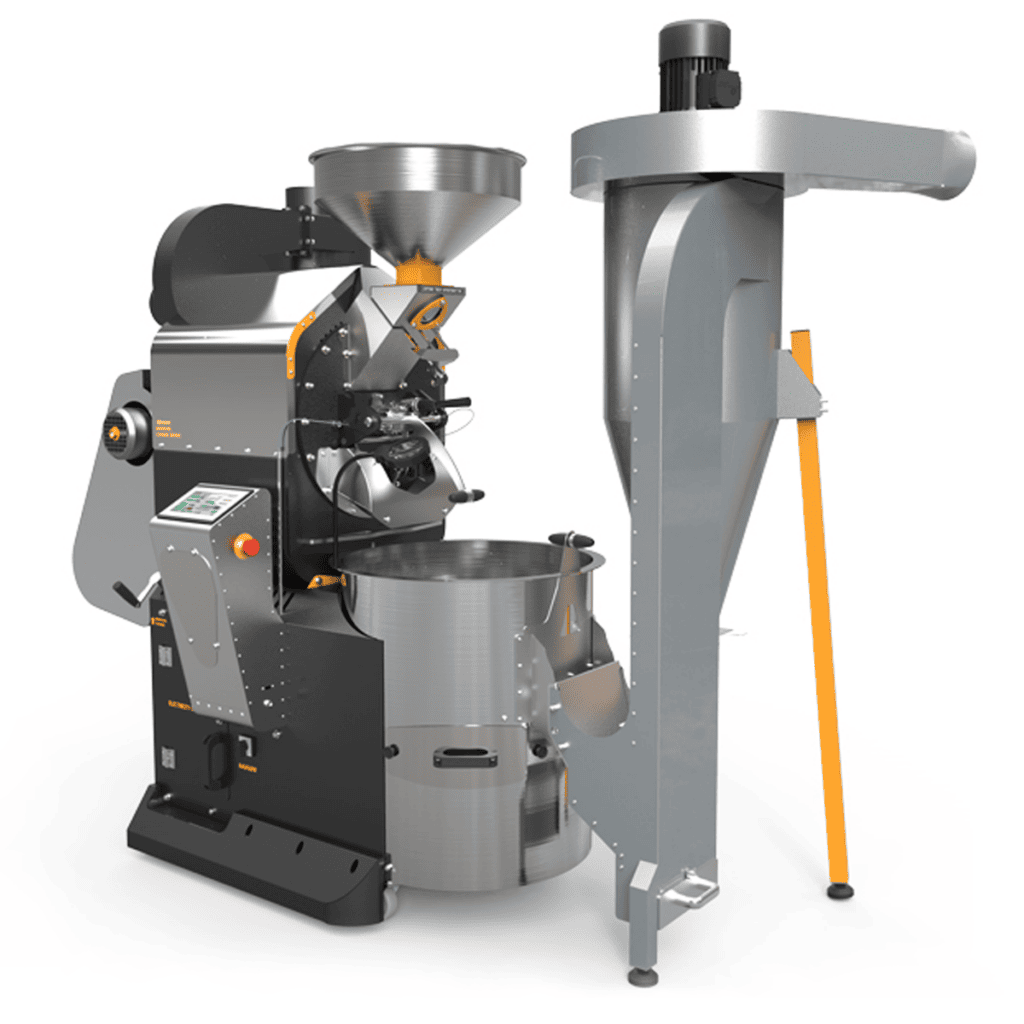

Touchscreen

The touchscreen control system allows you full, simplified control and monitoring of your roasting process.

Vortex

Drum air-inlet screens configured at vortex geometry to allow very efficient high-velocity air.

Full Modulation

Features a highly effective pre-mix turbo gas burner. This clean heat source provides maximum gas burning efficiency with minimum levels of carbon monoxide emission. Safe, economical and stable, it features many unique parameters for control and calibration.

Sub-Atmospheric Combustion Chamber

Sub-atmospheric pressure is maintained in the roaster during the roast cycle. By drawing a vacuum in the roaster, it allows uniformly better results that are not influenced by atmospheric humidity or atmospheric pressure.

Award Winning Technology

Coffee-Tech Engineering has won multiple awards within the world of coffee for contributions both in design and technological innovation. The Ghibli Line features these innovations as standard, integrated in every Ghibli roaster that gets built.

Vortex T04 Drum

Enhances the robust qualities of coffee, accommodating various roasting styles to yield richer aromas and an exceptional cup profile.

Technical Specifications

Batch Capacity

3-15 kg (6.6-33 lb) of green coffee

Roasting Cycle

14-17 minutes ± 4 batches per hour

Quality and Safety Compliance

CE, RoHS, EMC

Weight

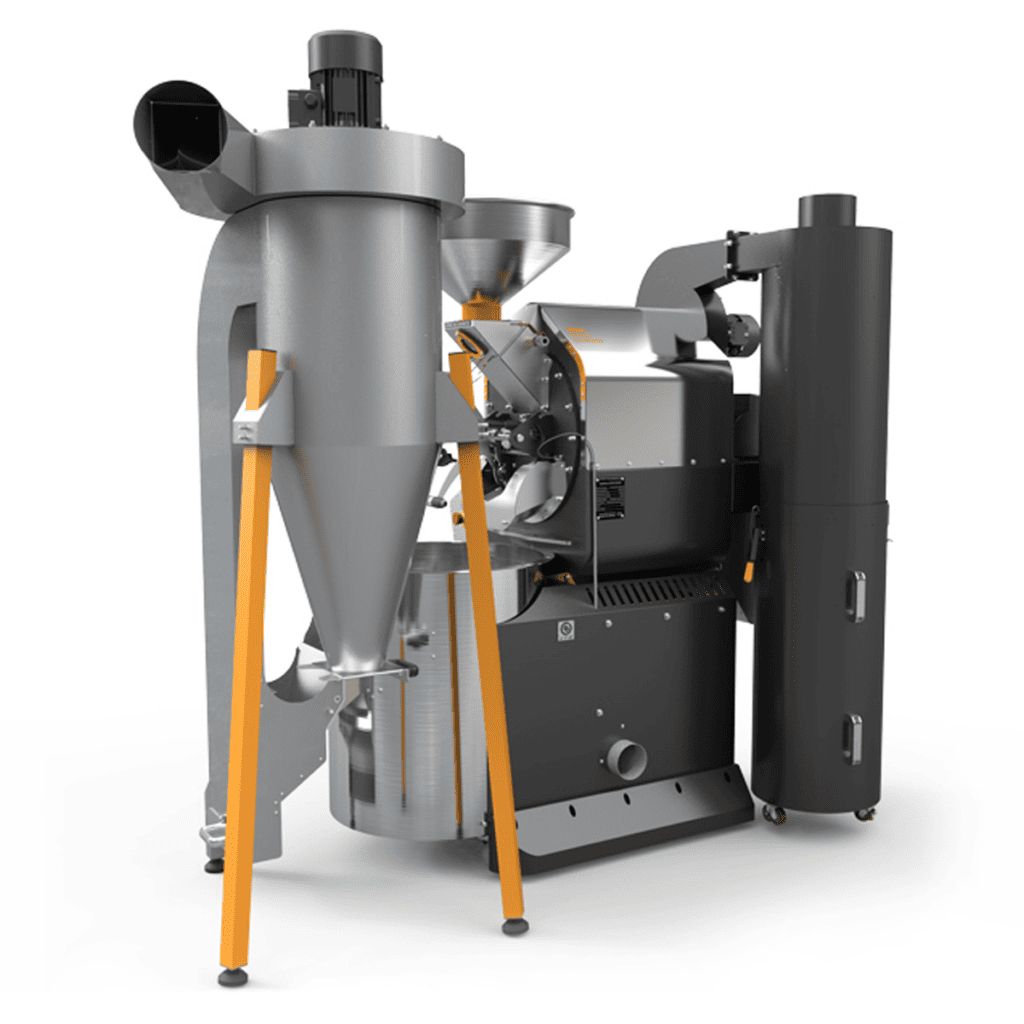

400 kg (882 lbs.) machine with cyclone

Body

Full precision metal work, top quality materials and hardware.

Gas Consumption

1-1.5 kg per hour of roasting

Heating Method

Gas: L.P.G. / Natural Gas (12-34 kw) fully modulated or single stage burner

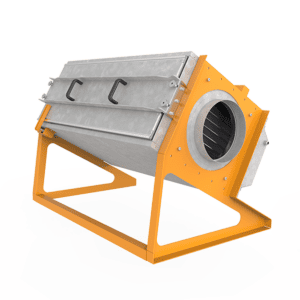

Chaff Evacuation

Full size, high-capacity cyclone chaff collector – for clean roasting and cleaner exhaust.

Drum Venting

Individual blower with digital variable speed control comes standard.

Cooling Agitation

Direct drive individual heavy-duty gear motor 1/3 hp

Cooling Blower

High-capacity cooling blower, cooling time is ±3 minutes

Safety

Safety drum discharger. In drum fire extinguisher.

Dimensions

114(w) X 173(d) X 182(h) cm. / 57(w) X 68(d) X 72(h) Inch. (With cyclone)

Electrical Specifications

50/60 Hz, 2500w, 3 phase, 230V /380V

Drum Housing

Sub atmospheric combustion chamber

Drum Operation

Individual, heavy-duty gear motor. Digital variable drum speed control comes standard.

Bearings

Four main bearings, two (F&R) precision dry bearings with zero tolerance for centring the drum; and two high temperatures, self-aligned bearings.

Also Available

– Wood/charcoal heating conversion

– Automated software

– Pneumatic doors

– Loading system

FAQs

Everything at Coffee-Tech is designed using 3D CAD; this enables us to be very precise with each and every aspect of the machine. Coffee-Tech Engineering takes pride in producing high-tech, efficient, and compact machines. Every single piece of our machines have a professional significance; we leave nothing to chance.

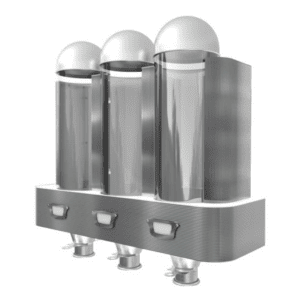

An Afterburner is a system used to eliminate (burn) smoke and odor coming from the coffee roasters’ exhaust system.

There is no definite answer to this question; this depends on where you are roasting and what your surroundings are. If, for example, you are roasting in a residential area, most probably you will need an afterburner (or the Avirnaki system if you are using a shop roaster). The need for an afterburner depends on many factors that vary from one country to another and sometimes even from one city to another – neighbors, local regulations, licensing etc. The best thing to do is inquire with your local authorities regarding your roasting facility plans.

During the processing of coffee, in producing countries, various foreign materials find their way into the green coffee bags – stones, metal objects, glass and more. These objects, if not removed, can bring serious harm to equipment such as grinders. A De-Stoner is the machine that pneumatically removes these foreign objects from the roasted coffee and drops them into a sieve. Our De-Stoner also comes with a frequency inverter that allows the user to adjust the airflow according to the coffee variety or roast degree.

The most preferable configuration is a straight-up duct (chimney), through the roof and free to the atmosphere. Side ducting is also possible but, if used, should follow some fundamental principles – contact us for further advice. The best material for ducting is double-walled stainless steel.

Additional information

| Weight | 900 lbs |

|---|---|

| Dimensions | 85 × 54 × 78 in |