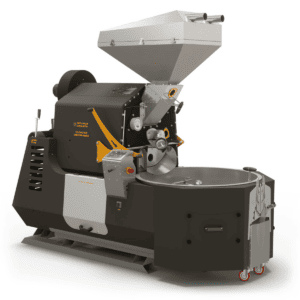

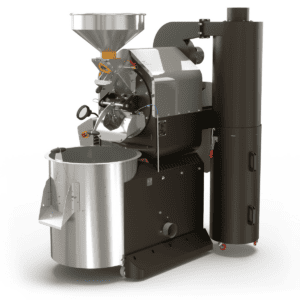

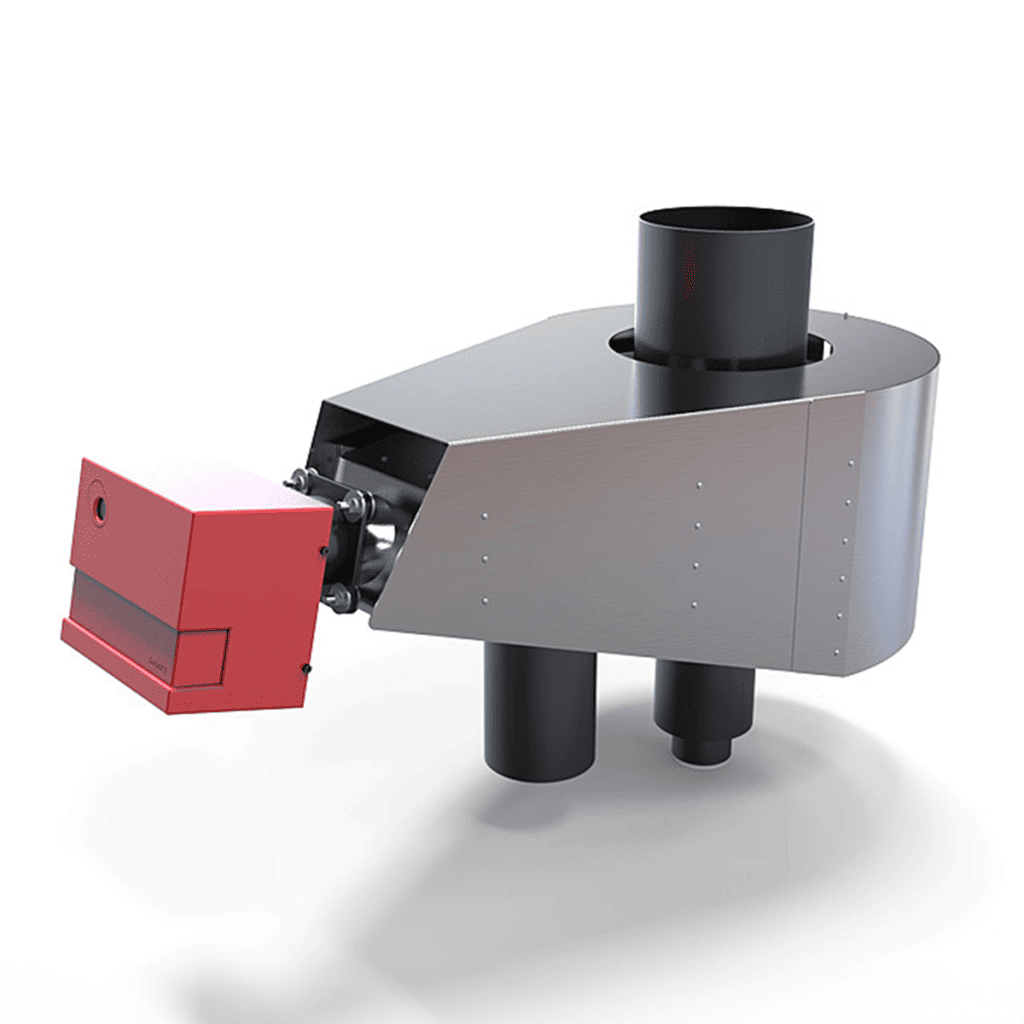

Highly efficient Afterburner for the Ghibli Commercial Roaster line

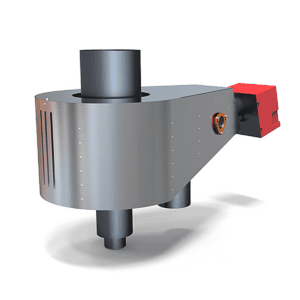

Coffee roasting pollution, determined as smoke, is characterized by a few properties such as steam, volatile aroma, vaporized oil, organic dust, ash and gases such as CO, NOx, SOx and others. Our afterburner is meticulously designed to greatly reduce these gases efficiently and accurately.

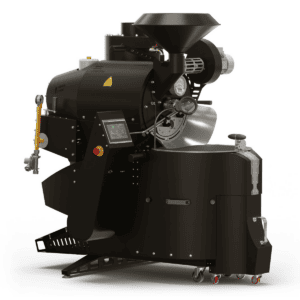

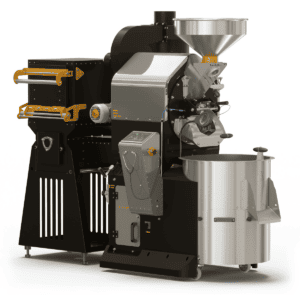

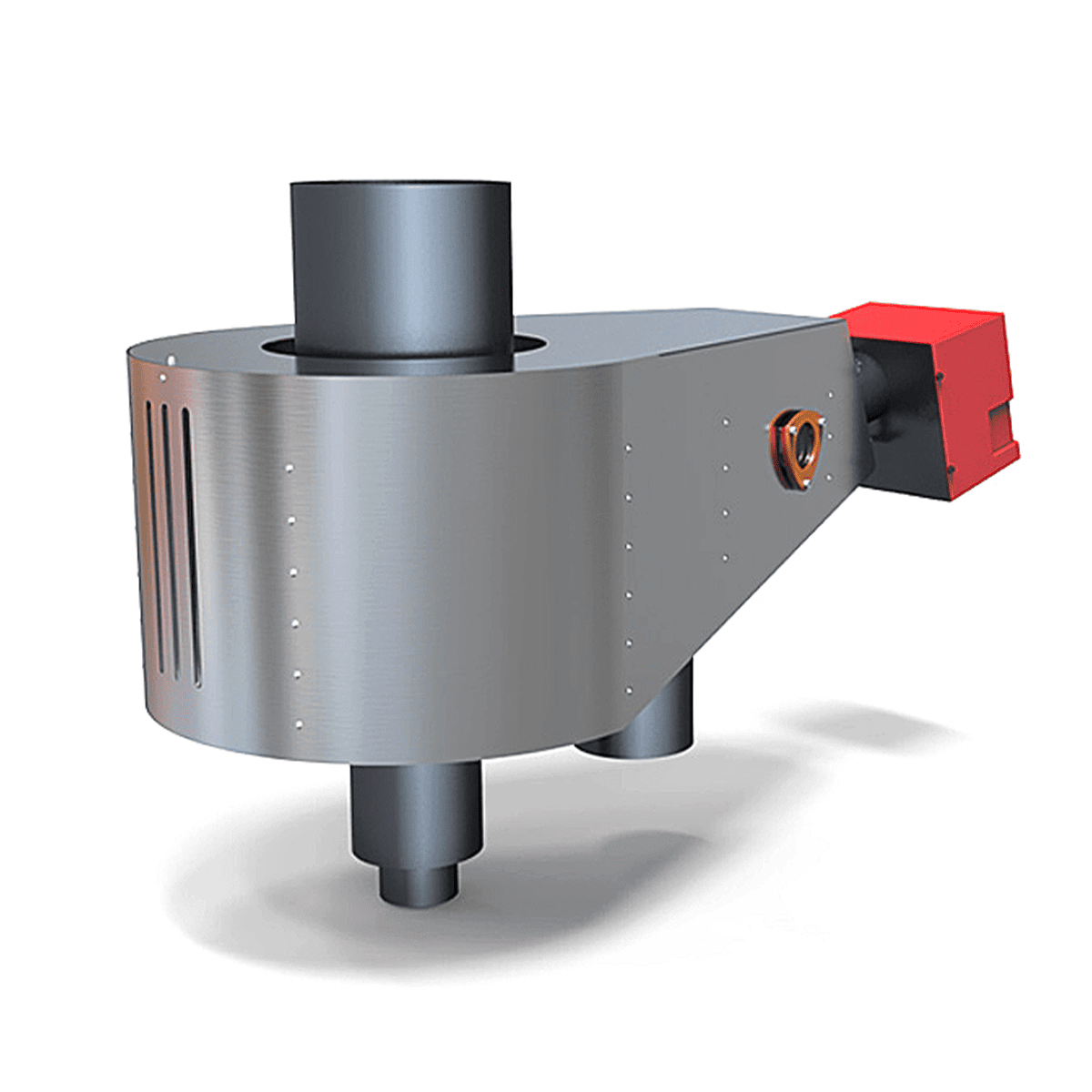

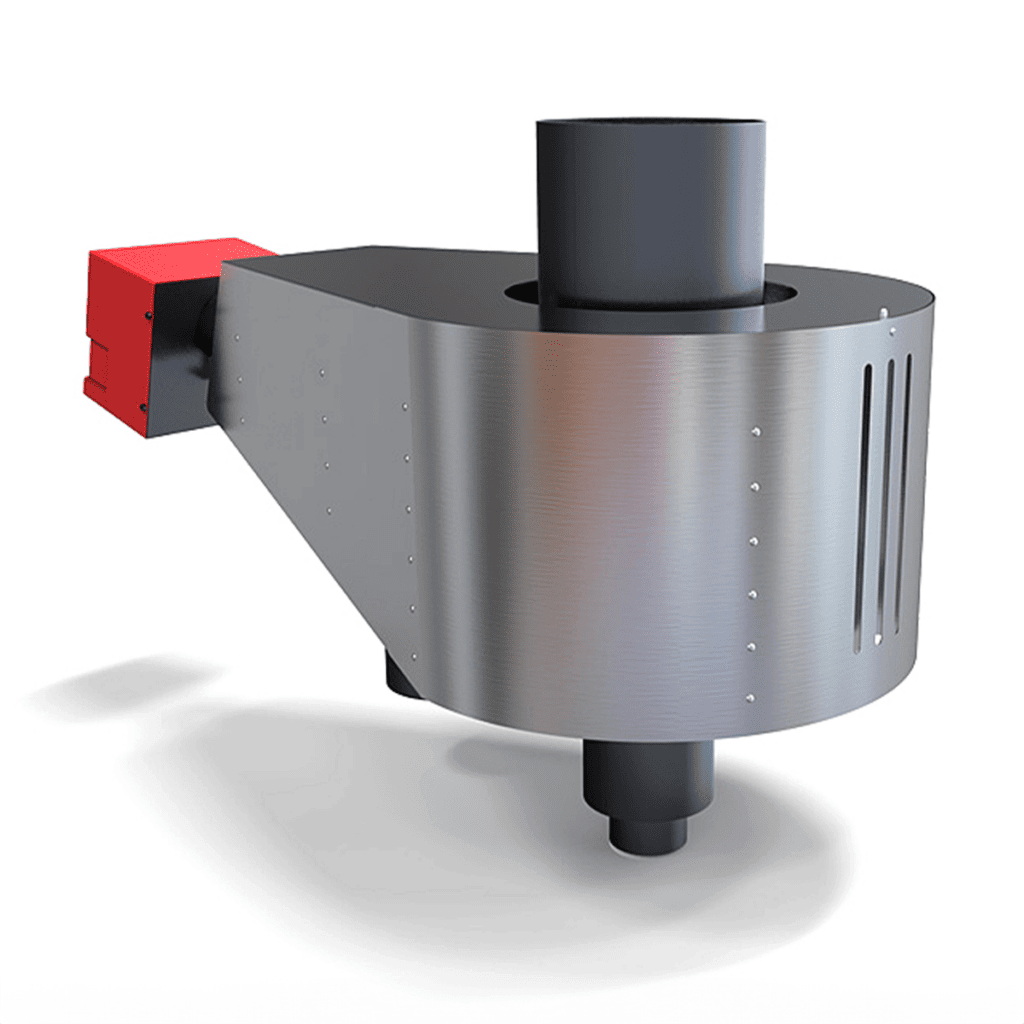

Most currently available afterburners are designed to treat the smoke coming from the roasting drum only, while the smoke from the cooling process is left untreated to the ambient with a separate duct. This afterburner absorbs the smoke from both sources within the machine – the roasting drum, and the cooling group itself. The result is zero smoke – emitted externally via a single duct facilitating installation, maintenance, and operation.

Installing an afterburner will ensure your duct remains clean and free from the need for periodical cleaning, which can turn into a major annual expense, although periodic inspection is required. In addition, a dirty and unmaintained duct exposes the entire building to a severe risk of fire. Running a roaster without an afterburner and without cleaning the duct is not an option, and this must be taken into consideration when calculating operational costs.

Who needs an afterburner?

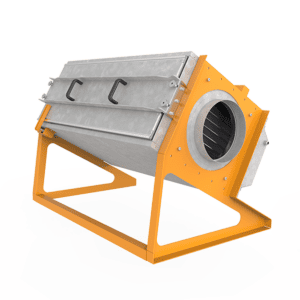

Anyone who is striving to produce high-quality coffee. Producing quality coffee needs requires fresh secondary air, a clean dedicated and controllable flame, and a high rate of conduction, a much higher than gas recirculating system method is permitted. Thus, a roasting machine needs its own burner and burnt gases, while pollution should be treated externally and away from the roasting drum. For this reason, the afterburner should be a separate unit, located apart from the roaster as placed after the cyclone/chaff collector.

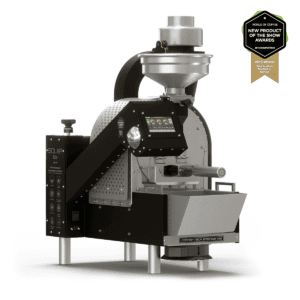

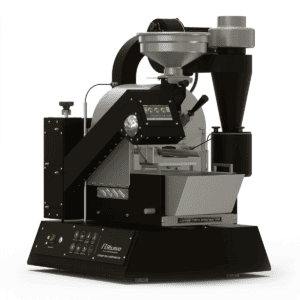

The Afterburner is located directly above the exhaust of the chaff collector. This arrangement takes no extra floor space than occupied by the machine. Afterburners are available for all sizes and batch capacity roasters, from our smallest commercial roaster to the fully industrial roasting line.

This afterburner is built to last, with the best materials for years of lasting service. These devices are exposed to a high rate of oxidation and extreme conditions, allowing no smoke or odours to escape. The design is called a Fullflow which adds no resistance to the machine’s aspiration capability. In many cases, it will save a measurable length of duct and chimneys to keep the smoke away, whereas with the Afterburner the duct can be shorter as there is no longer any pollution.

Features:

- Heavy-duty construction and high performance

- Efficient gas consumption

- Safe and stable CE approved gas burner

- Conducts smoke both from cooling and exhaust simultaneously (Ghibli R15)

- Low NOx low Carbone monoxide emission

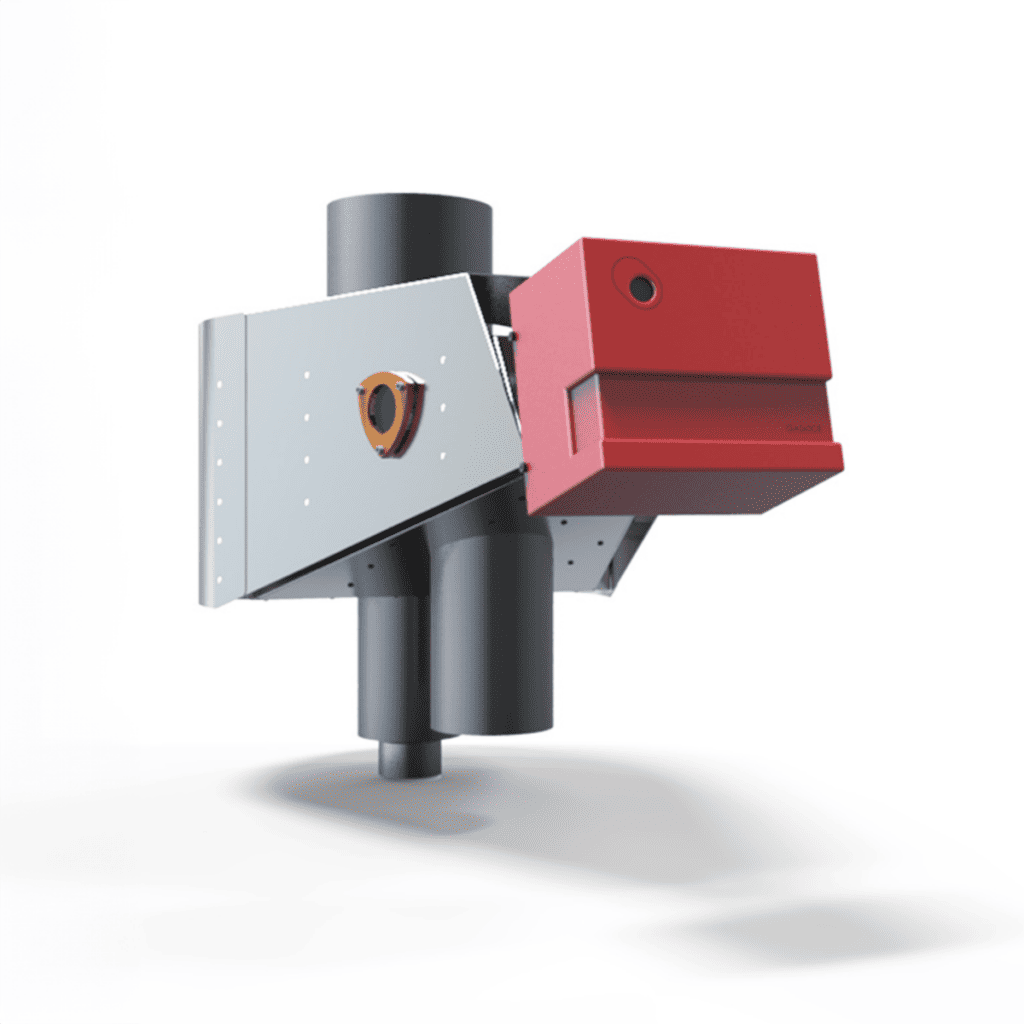

- Large inspection lens for flame monitoring

- Most compact in size, footprint saver

- Flanged chamber for easy access for internal servicing

- Futuristic and modern design

- Shielded for heat dispersion

Technology & Features

Low Energy Consumption

Energy efficient product, low electricity consumption

Green Product

(Optional) This product excels in its low rates of emission and air pollution.

Smoke-Free

(Optional) An efficient and green smoke elimination system.

Maintenance Free

No recurring upkeep for continuing function.

Technical Specifications

Materials

Carbon steel/Stainless steel/Aluminum/Ceramic insulation up to 1200°C

Dimensions

64(w) x 134 (d) x 420 (h) cm Exhaust diameter: 258mm 25(w) x 53(d) x 17(h) Inch Exhaust diameter: 10

Weight

90Kg (198 lb)

Electrical Specifications

Single phase 220-240VAC 300W 50/60hz