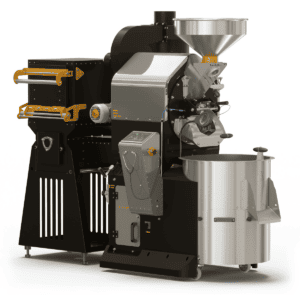

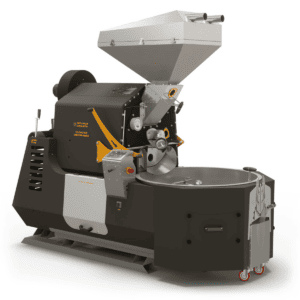

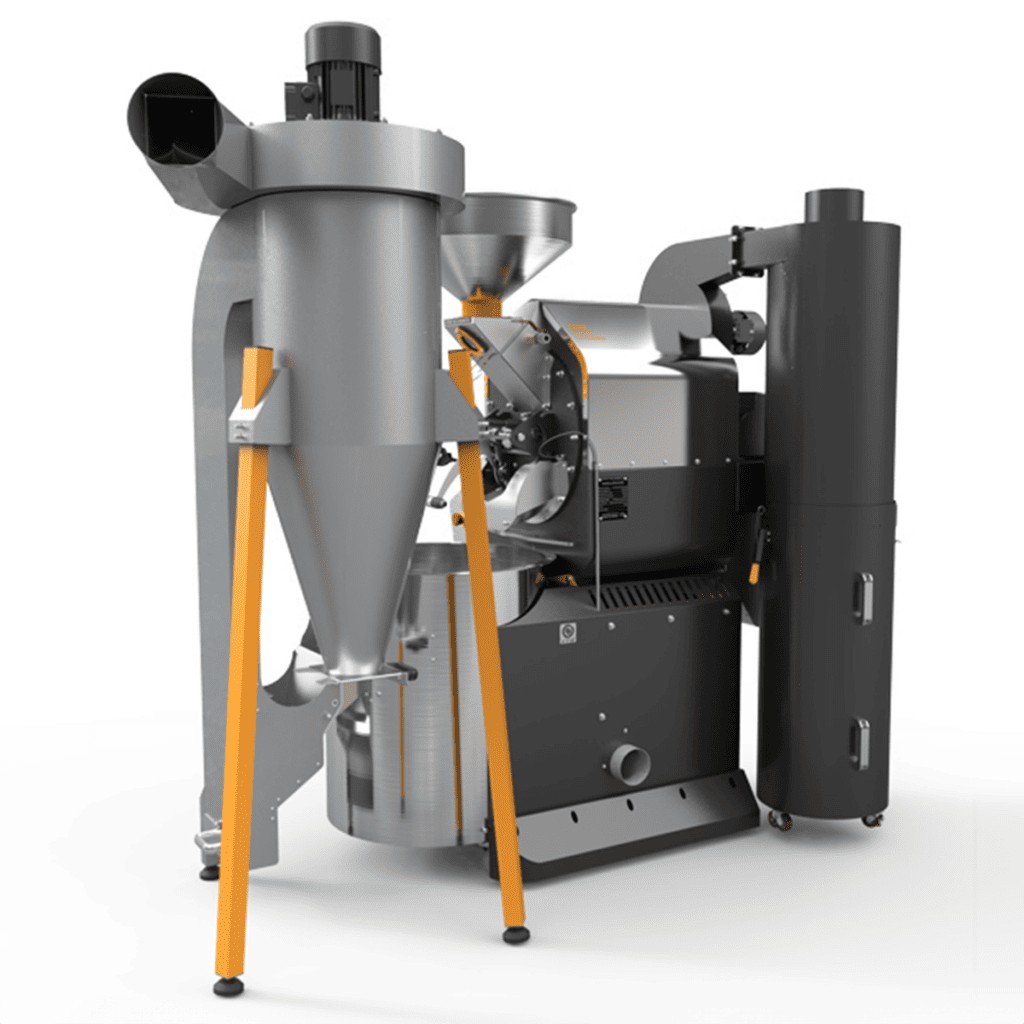

A fully integrated, heavy-duty coffee destoner.

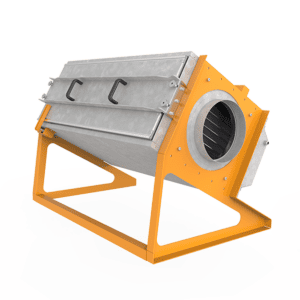

Coffee Tech Engineering’s destoner works on a gravity principle by using the light weight of the coffee beans to detect other foreign objects that might be found, such as stones and metals. De-stoner is equipped with an adjustable large-volume air blower, creating a vacuum tunnel for separating the coffee beans from heavier-weight foreign particles. Consequently, we receive a clean product containing 100% pure coffee, without risking our customers or their equipment.

This destoner is built using heavy-duty materials, calibrated to the highest accuracy achievable. Thanks to its clever design and engineering, a correct ratio between the beans’ screen, their surface area and the quantity of air is maintained, making the destoner sensitive to the smallest stones that might be found inside the coffee. The user regulation interface is performed from your Coffee-Tech Engineering roaster’s touch screen or using the Destoners digital frequency inverter for consistency, repeatability, and accuracy, and with a resolution of 0.1Hz you can be certain that your destoner will perform its task to perfect guaranteed results.

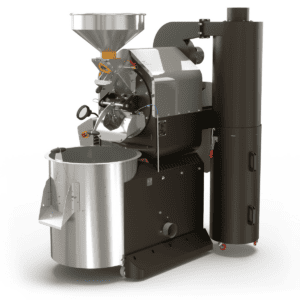

Integration

The Destoner is fully integrated onto your roaster, connected directly to the beans’ exit from the cooling pan. Evacuating the cooled beans directly to the de-stoner without a middle stop in the process. All you need to do is to open the cooling group door and push the de-stoner button. The operation switch, de-stoner power alimentation and frequency inverter interface are all integrated with the machine, and you will need no extra infrastructure or installation.

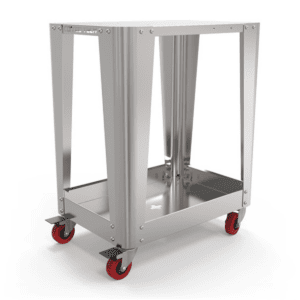

Small footprint

The destoner excels in a small footprint to save floor space at your roastery.

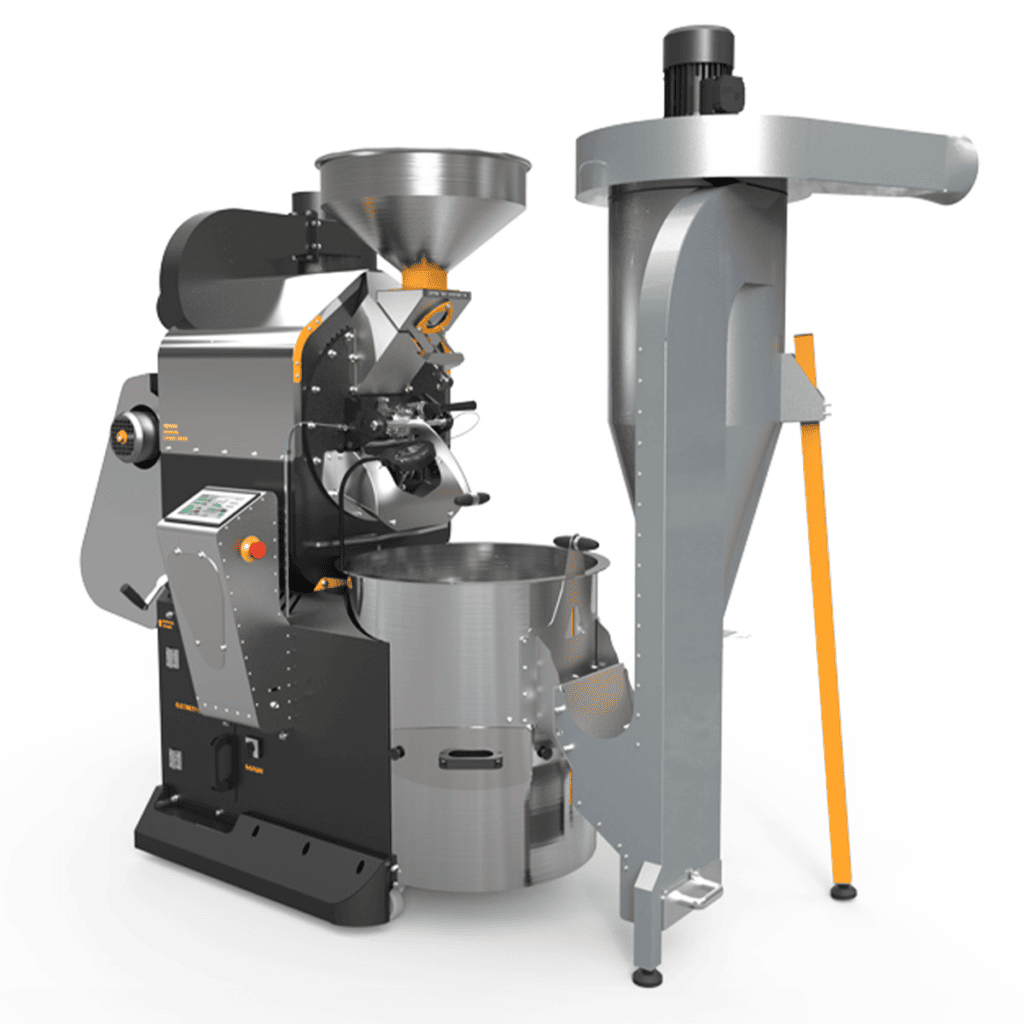

User-friendly

Coffee-Tech is always thinking about the roastery’s day-to-day routine and performance and how we can improve and achieve higher efficiency. That’s why we integrated the Destoners operation from the roaster’s touchscreen control panel. As a roast master, working at the roastery you could be multi-tasking all day long. This includes operating the roaster, preparing the next batches, and making sure you are keeping your roaster working continuously. These batches won’t be preparing themselves, so operating the gear from one central point is something that you will enjoy and benefit from, eliminating the need to move between different control boxes and switches.

Why you need a Destoner

From the moment the coffee beans are picked until they reach the consumer’s serving cup, it takes a long road with several stopping points where the beans need to be processed and sorted. These processes include harvesting, picking, conveying, carrying, drying, washing, pulping, sorting, bagging, and transporting to the green beans’ warehouse.

Coffee, as with many other natural commodities, contains a minor percentage of particles such as small stones, falling pieces of metal from machinery, wooden sticks, and similar. Despite the sorting and bagging process, some foreign objects find their way into the coffee bag and the beans inside, and eventually end up in landing inside the coffee roaster drum.

All coffee beverages require roasting and grinding before preparation.

If a stone or a similar foreign object reaches the grinder, it might cause severe mechanical damage or even complete dysfunction of the grinder itself. Moreover, it can endanger the roastery’s reputation and harm the brand value in the eyes of the consumer.

The purpose of the destoner is to separate these stones and particles from the roasted coffee before the roasted beans are bagged or ground.

Technology & Features

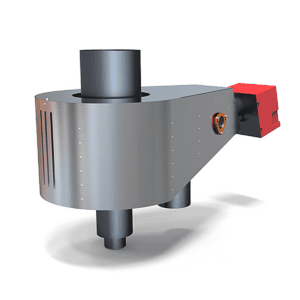

Blower Speed Control

Electronic drum venting control, setting convective heat percentage while roasting

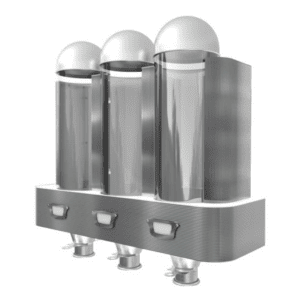

Technical Specifications

Materials

Stainless steel/Carbon steel

Electrical Specifications

Single phase 220-240VAC 50/60hz

Holding capacity

30Kg (66 lb)

Weight

100Kg (220 lb)

Dimensions

74(w) X 40(d) X 1950(h) cm / 29(w) X 16(d) X 768(h) Inch