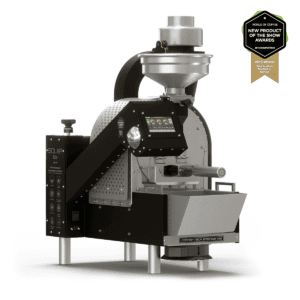

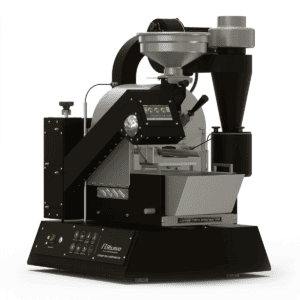

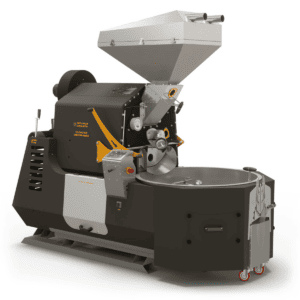

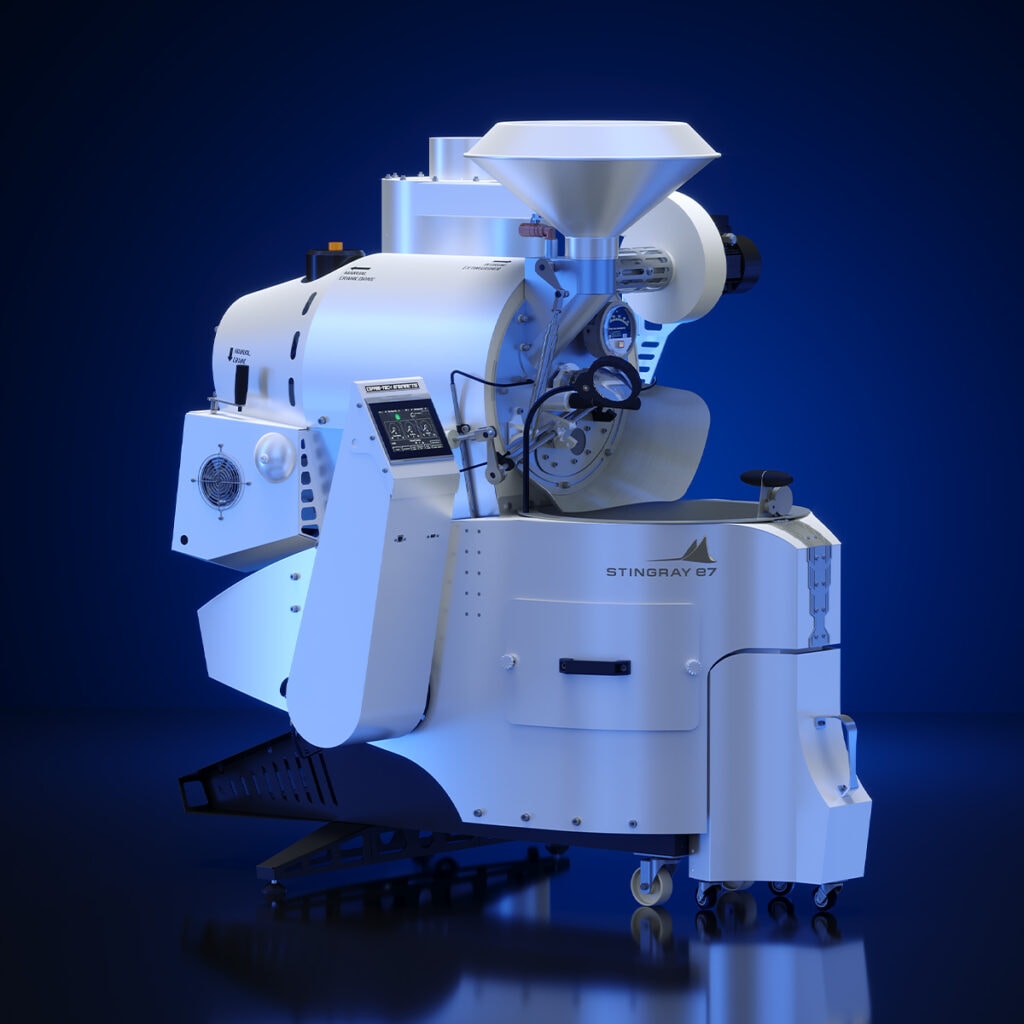

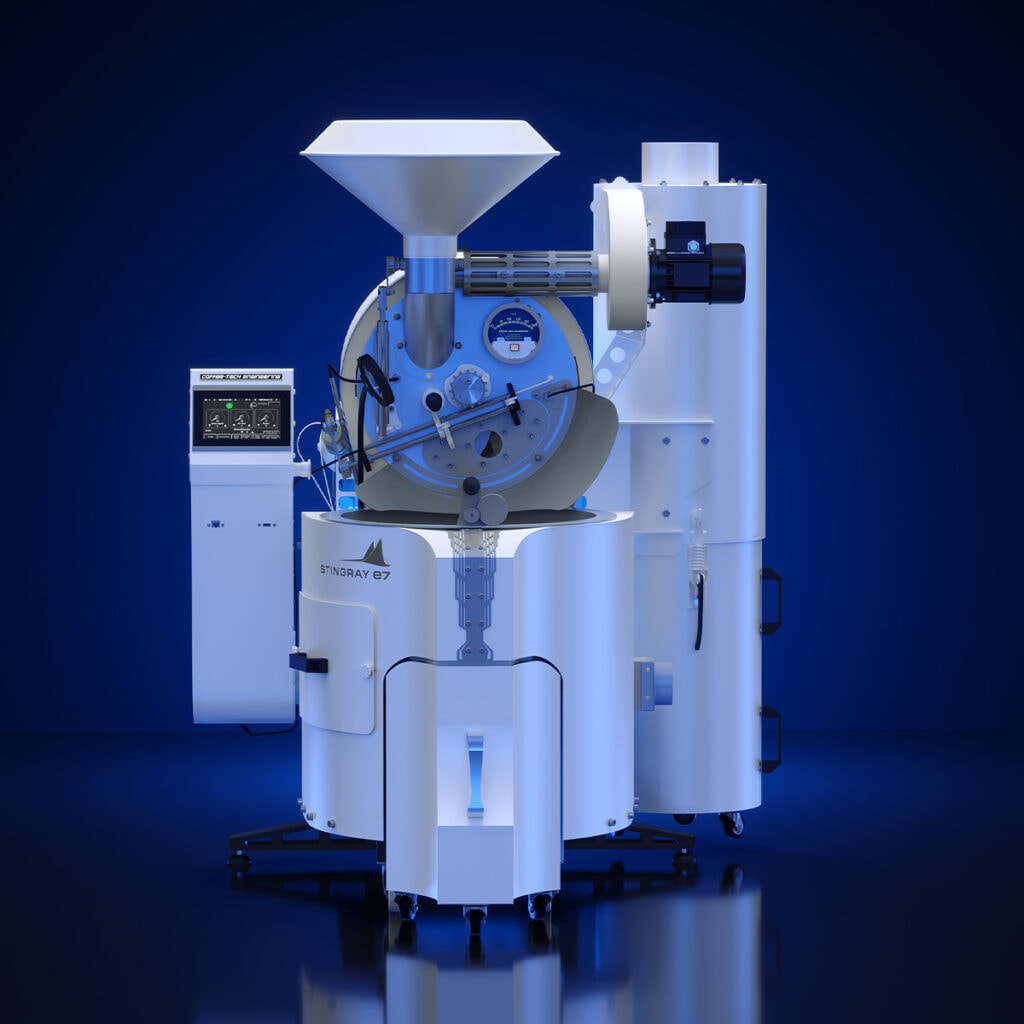

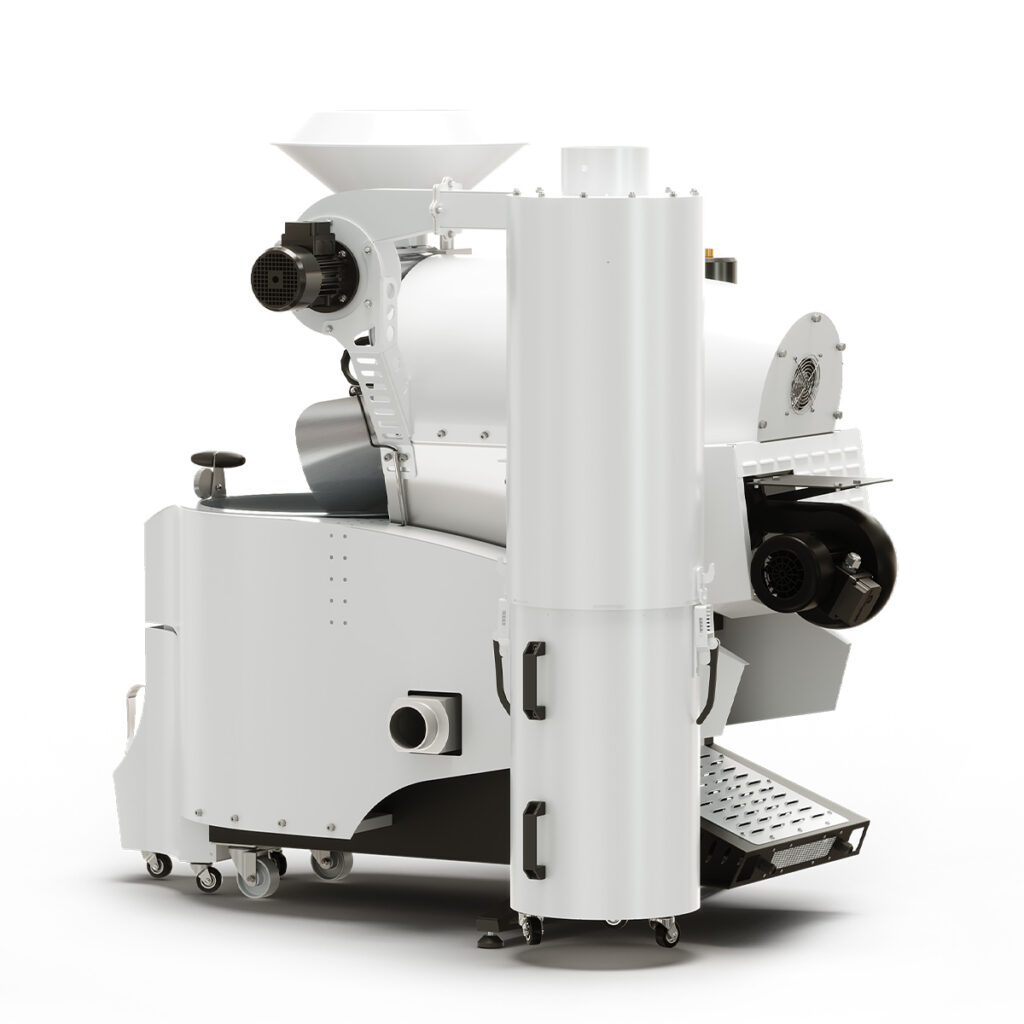

Stingray E7 Electric Shop Roaster

Leasing options are available through our partners.

1-7Kg Batch Capacity

Electric Heating

Touch Screen Control

“The Stingray is an electric coffee roaster, engineered with precision to deliver exceptionally consistent roasts. Our exclusive ElectroFlame technology and smart Heat Management Software are a breakthrough in the industry, pairing a powerful electric burner with a meticulously designed ceramic drum housing to create an unparalleled roasting experience and an exceptional cup profile.”

– Ram Evgi, founder and CEO of Coffeetech Engineering

Technology

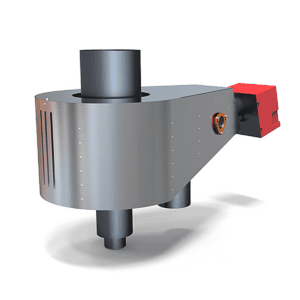

Meet ElectroFlame: Electric roasting redefined.

Introducing ElectroFlame technology, a breakthrough that brings electric roasting to a new level. Engineered to preserve the distinguished CTE cup profile, ElectroFlame combines a high-performance electric burner, housed within a custom-designed ceramic drum housing.

With a fully insulated chamber, the drum operates at sub-atmospheric pressure, ensuring exceptionally consistent roasting.

With the Stingray, roast masters gain complete precise control over the profile, enabling every roasting style, and delivering the entire spectrum of flavor and aroma.

Electric Smokeless Roasting

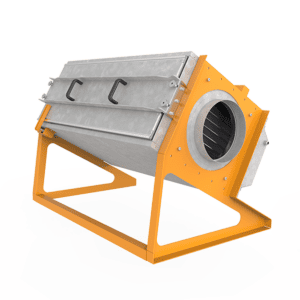

A fully electric Smokeless System: Zero Emissions, Maximum Sustainability.

For a truly sustainable roasting experience, the Stingray integrates seamlessly with the Commercial Avirnaki—a fully electric smoke elimination system designed for maximum efficiency and durability.

Providing a cleaner, more efficient alternative to afterburners, the Avirnaki operates with zero reliance on fossil fuels while completely eliminating harmful emissions like CO and NOx.

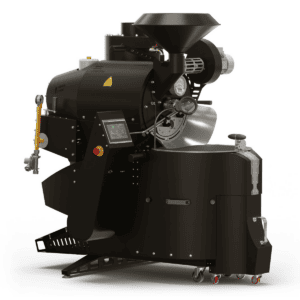

Superb for easily repeating your automated profiles across a vast roast range, this lab and shop roaster is designed for accuracy, efficiency, and reliability. The FZ94 Evo propels your evolution as a roast master.

Heat Transfer Method

The best of conduction and convection: optimized for precision and control.

The Stingray E7 is a revolutionary conductive roasting system that utilizes an efficient, low-volume at high-pressure airflow to precisely direct heat within the roasting process.

This innovative approach balances the benefits of conduction and convection, ensuring a smooth, controlled, and precise roasting process.

The result? coffee that is exceptionally rich, clean, complex, and well-developed, free from excessive wood taste, smog, or cereal-like notes.

Efficiency

Optimizing Roasting Efficiency Through Thermodynamics and Heat Preservation.

The Stingray is designed for unmatched energy efficiency, with integrating state-of-the-art thermodynamic heat preservation and proprietary heat management software. This advanced system ensures consistent, high-performance roasting while minimizing energy consumption greatly.

Equipped with an exceptionally efficient and powerful burner, the Stingray maintains reliable, long-term performance. Precision-engineered for maximum efficiency, it delivers remarkably low energy usage per cycle—without compromising on power or roasting quality.

User Protection

Setting New industry Standards in user safety

As an industry leader in coffee roasting machines, we set the highest standards for user safety. Our roasters are engineered with stringent safety measures, each product comes equipped as standard with multiple built-in safety mechanisms—at no additional cost.

Most importantly, our sub-atmospheric roasting chamber prevents gases and pollutants from escaping into the user’s environment, protecting roastmasters from excessive exposure to harmful emissions. At Coffee-Tech Engineering, we take every measure to ensure a safe roasting environment for you and your staff.

Technology & Features

Drum Roasting

The primary roasting method in this roaster is drum roasting conduction.

Conduction Heating

Heat is delivered by direct contact between the beans and the hot surface of the drum

Convection Heating

Hot air is forced through the beans.

Ceramic Chamber

A ceramic coated chamber surrounding the drum ensures thermal stability and efficiency.

Sub-Atmospheric Combustion Chamber

Sub-Atmospheric pressure is maintained in the roaster during the roast cycle. By drawing a vacuum in the roaster, it allows uniformly better results that are not influenced by atmospheric humidity or atmospheric pressure.

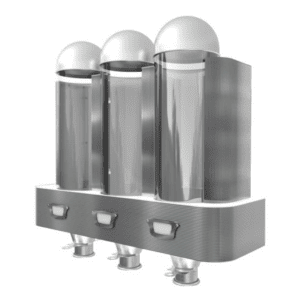

Roast Data Logger

A PC-supported profile software, featuring bean temp’, drum temp’ and rate-of-rise graph.

Multi Point Temperature

Temperature probes gather thermal data from the beans, exhaust & drum space.

Vortex

Drum air-inlet screens configured at vortex geometry to allow very efficient high-velocity air.

Blower Speed Control

Electronic drum venting control, setting convective heat percentage while roasting.

Drum Speed Control

Electronic drum speed control, setting conductive heat percentage while roasting.

Electric Heating

Preserving the highest roasting quality utilizing only electricity. Safe, Green, Reliable, no gas required.

Smoke-Free (Optional)

An efficient and green smoke elimination system.

Low Energy Consumption

Energy efficient product, low electricity consumption.

Green Product

This product excels in its low rates of emission and air pollution.

Automatic (Optional)

Operation is run automatically and handled by an Automatic Roasting Management Software.

Manual Safety Crank

The manual safety crank allows you to manually evacuate your beans should your roaster lose its power supply.

In-Drum Extinguisher

Safety device, a live waterline connected to the drum in case of in-drum fire.

Touchscreen

The touchscreen control system allows you full, simplified control and monitoring of your roasting process.

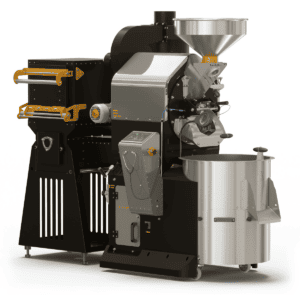

Award Winning Technology

Coffee-Tech Engineering has won multiple awards within the world of coffee for contributions both in design and technological innovation. The Ghibli Line features these innovations as standard, integrated in every Ghibli roaster that gets built.

Low-NOx

An infrared flame screen is the cleanest, most efficient way to produce energy out of any type of fuel. Ultra-low NOx specs fulfill the strictest pollution standards. It may not mean much at this point, but it is all about your health as the operator: your surroundings and your coffee. No soot accumulation in the drum to coat your coffee, none of the harmful CO produced during operation, no irritated red eyes at the end of the day. Burner runs the full gamut, at any stage, from low power to overkill, controlled by your choice.

Thermodynamic Drum (Optional)

The most advanced drum available in today’s industry. Built from two layers of mild steel with a middle layer of pure copper, it has extremely high thermal absorption and heat conduction characteristics. In contrast to standard drums in which roasting is performed by direct, limited contact between the beans and the drum. The Thermodynamic Drum exhibits a unique scheme of sophisticated heat conduction applied to a wider contact surface between beans and drum. Heat is transferred via the copper layer creating a 1.4 mm gap between the heat and the beans, removing any risk of burn marks. This drum excels in producing an evenly roasted batch of superb beans, allowing a higher range of temperature operation, and writes its own new language in thermal dialog – just imagine, reflected heat conduction.

Technical Specifications

Batch Capacity

1– 7 kg (2.2 – 15.5 lbs.) of green coffee.

Electrical Specifications

50/60 Hz, 18,000W, 380V

Materials

Full precision metal work, top quality materials and hardware

Heating Method

ElectroFlame Technology

Cooling Agitation

Individual, heavy-duty gear motor

Roasting Cycle

13-17 minutes ± 4 batches per hour

Drum Housing

Sub atmospheric combustion chamber

Bearings

Heavy duty, precision bearings. Long intervals between required maintenance

Process Quality Control

Large pyrex lens for easy monitoring of roasting progress. Digital, double temperature controller for heat control allows determining temperature range for roasting

Safety

Safety drum discharger, in drum extinguisher, emergency stop button

Dimensions

121 (w) X 165 (d) X 153 (h) cm / (48” (w) X 59” (d) X 66” (h) with cyclone

Weight

255 kg (562 lb)

Heating Method

ElectroFlame Technology

Quality and Safety Compliance

CE, RoHS, EMC

Chaff Evacuation

Full size, high-capacity cyclone chaff collector

Cooling Blower

High capacity cooling blower, cooling time is ±3 minutes

Drum Operation

Individual, heavy-duty gear motor. Digital variable drum speed control comes standard

Additional information

| Weight | 650 lbs |

|---|---|

| Dimensions | 50 × 65 × 70 in |